How Often Plow Garden With A Tractor

The Science and Art of Plowing

by Professor A.M. TenEyck, Agronomist

Deere & Company, Moline, Illinois, USA, 1909

Ever since the publication, last-century, of Faulkner's The Plowman's Folly, dispute has existed about the merits of any plowing whatsoever. I personally have seen frequent appropriate and excellent applications of the moldboard plow. This material was published by John Deere as a combination educational and promotional brochure. It contains some very good stuff. It is our hope that you will use this information wisely and well. LRM

When and How to Plow

Plow, if possible, when the soil will drop from the moldboard in a mellow, friable condition.

It is better to plow when too dry than when too wet, and don't delay the work too near seeding time.

Plowing should be shallow when it precedes seeding but a short time.

Plow as long before planting as possible, so the soil will have ample time to settle into good seed-bed condition and store up moisture for the coming crop.

Deep plowing enlarges the moisture reservoir and gives more root room—see article.

Late fall and winter plowing destroys weeds and many insects.

When a green crop or heavy coat of manure is to be turned under, plow early so the organic matter will have time to decay and the soil to become settled before seeding.

Have the seed-bed loose and well pulverized on top, but firm and well packed underneath.

The Soil

Feeding plants is a science based upon a knowledge of plant life and the nature of the soil.

The farmer is most concerned with the soil and its treatment — these he controls.

What about the soil? It is not all plant food, but largely an inert mass of very small particles of rock brought to its finely pulverized condition by ages of weathering and decomposition.

Through this mass are distributed small quantities of mineral elements called plant foods. Besides these, a fertile soil contains organic matter called humus. This substance is the basis of soil nitrogen, which is the most important element of plant food, being the one most quickly exhausted.

Humus (rotted vegetable matter) has a great influence on the physical condition of the soil. It gives that dark, fertile appearance, holds the moisture, tends to produce a mellow, warm condition, and is the medium through which bacterial life exists. These bacteria are essential to plant growth, and thrive only in the presence of a good supply of humus. Soils which have no humus are "dead" and unproductive.

Texture of the soil is nearly always more important than mere richness. Many "worn out" lands have simply been robbed of their humus. They still contain an abundance of mineral plant food. Others have been injured by careless or faulty management.

The maintenance and improvement of soil texture depends more upon plowing than upon any other tillage operation. Plowing adds neither humus nor plant food, but if done right, will keep the soil in good tilth and make plant food available.

What Good Plowing Does

It pulverizes and mellows the soil.

A finely divided, mellow soil is more productive than a hard, lumpy one of the same chemical composition, because it holds more moisture; gives plant roots more feeding ground; has a more constant temperature. It also promotes nitrification and the development of available plant food.

Plowing, especially in the spring, tends to ventilate, warm and dry the seed-bed. If properly done, the mellow mulch formed prevents evaporation from the deeper soil, thus saving tons of water for the use of the crop.

Deep plowing brings up new stores of inert plant food, enlarges the moisture reservoir, deepens the seed-bed, gives more root-room and more material for the soil bacteria to convert into available plant food. Deep plowing, or subsoiling, serves to break up an impervious hard-pan and favors the absorption of moisture.

Fall plowing destroys many weeds and injurious insects. The latter are even more readily destroyed by winter or early spring plowing.

Proper and timely plowing is the most efficient and practical means of preparing a suitable seed-bed for nearly all farm crops.

The best way to build up the productivity of exhausted soils is to plow well, add humus and work up a physical condition suitable for the best growth of plants. After this is done the application of concentrated fertilizers may give profitable returns, but they should not be used to start with.

How to Plow

Plow intelligently.

Do not cut and cover. Make no skips.

If the plow is thrown out, back up or turn about and clear the furrow — it will pay in extra yield.

Do not plow out or around the field every year. Reverse the plowing each year so as to leave a dead-furrow through the center one year and a back-furrow the next.

Spring plowing should be so done as to avoid tramping on the plowed ground as much as possible. It is better, therefore, to do back-furrowing in the spring.

In starting a back-furrow, first throw out a shallow furrow, then reverse the direction, throwing the furrow in and plowing a little deeper. This prevents ridging.

In finishing a land, unless the purpose is to leave a deep dead-furrow for drainage, turn a shallow furrow back into the dead-furrow. The bare subsoil will produce little or no crop.

Poorly drained fields, or those in regions of great rainfall, may be plowed in narrow lands, making high back-furrow ridges and deep deadfurrows. If necessary, such lands may be plowed this way two or three years in succession. This elevates a large portion of the surface and gives better drainage over the whole area.

There seems to be no special advantage in having the trash sticking out at the edges of the furrows. A field looks better and is planted much easier when all trash is covered. The proper use of the jointer usually helps to accomplish this result. This attachment is valuable also for plowing sod.

When to Plow

It is usually a good plan to plow a considerable time before planting, so the soil may store moisture and settle into good seed-bed condition. This practice allows for surface tillage, which destroys weeds and makes plant food available.

It is not wise to depend upon plowing immediately before seeding, because the conditions of the soil and weather may interfere, delaying planting beyond the time that the seed should be in the ground.

There is a "best time" to plant each crop. The successful farmer will prepare his soil and await that time, for he knows it will never wait on him. It has been the writer's experience that success in growing crops depends more upon doing the right thing at the right time than upon any other controllable factor.

A good rule, but it cannot always be followed, is to plow when the soil is in such a condition that it will drop from the moldboard in a mellow, friable condition. It is usually better to plow when too dry than when too wet. However, a light, mellow soil or a coarse sandy soil may be improved by plowing when wet, because the compacting effect of the moldboard makes it less loose and porous.

Clayey, heavy, or sticky soils should never be plowed when wet, if it can be avoided, because the particles are so firmly packed together that drying produces hard clods, which are nearly impervious to plant roots, air and water.

There is one exception to this rule. In the case of late fall or winter plowing the freezing of the wet soil causes it to break up into a mellow, friable condition.

If plowing cannot be done early, cultivation of the unplowed land with a disc harrow will prevent drying out to a marked degree. The mulch thus produced prevents, to some extent, the escape of moisture and favors the absorption of any moisture that may fall. Such mellow surface is in a favorable condition for making a good connection with the subsoil when the furrow-slice is finally turned.

Depth to Plow

Deep plowing should be done with purpose and intelligence, because it is not always the right thing to do.

In dry seasons deep spring plowing, unless great care is taken to pulverize and repack the seed-bed, may result in crop failure, because the loose soil dries out and capillarity is broken, preventing the furrow-slice from securing moisture from the subsoil rapidly enough to sustain the growing crop.

Loosening the soil by deep plowing favors the absorption of moisture, but if rains do not come in time such land will suffer from drought more quickly than though it had been plowed shallow.

Shallow soils should not be plowed deep enough to bring up too much of the subsoil at one time. A soil may be gradually deepened, but if too much of the subsoil is brought to the surface at once it will reduce the productiveness for a year or two, till the inert matter is decomposed and mixed with the fertile soil.

It is advisable to vary the depth of plowing, and even to subsoil heavy land, in order to break up the furrow-sole, but it is often just as important to plow sandy land the same depth year after year in order to produce a more impervious condition, which will prevent too rapid percolation, leaching and loss of soil moisture.

As a general proposition, plowing should be shallow when it precedes planting only a short time.

Plow deep in the fall.

A long interval between plowing and seeding allows the soil to settle sufficiently, while freezing and thawing mellows the raw, hard subsoil which has been brought to the surface.

The relative depths of plowing may be stated as follows:

- Shallow plowing… 3 to 4 inches.

- Medium plowing… 5 to 6 inches.

- Deep plowing… 7 to 8 inches.

Cases are rare when it is necessary or advisable to plow deeper than eight inches.

Plowing Sod

There are two general methods of plowing sod — shallow, breaking two to four inches in depth, and deep, breaking five to six inches in depth.

The first method is used when it is desired to kill the turf and then "back-set" before seeding. Back-setting buries the sod and brings up enough mellow soil from below to form a seedbed.

The second method secures sufficient soil so replowing, or back-setting, is unnecessary, the disc harrow being used on the sod in preparing the seed-bed. With this method of breaking it is important to set the furrow-slices slightly on edge, because this favors the pulverizing of the surface with a disc or other tillage implements.

The first method is usually preferred for breaking raw prairie.

Breaking may be done either in the spring or fall, depending on the nature of the crop to be planted.

Late spring breaking is preferred in the west, where the land is usually allowed to lie fallow during the summer and is sown to wheat in the fall, after being back-set and harrowed.

For a summer crop, fall or winter breaking is usually preferred.

Fall and Winter Plowing

Soils which have a tendency to drift should not be plowed in the fall.

Heavy clay or gumbo may be improved in texture by late fall or winter plowing.

Fall and winter plowing destroys harmful insects, results in a well-settled seed-bed, and the accomplishment of a part of the labor of preparing the land when other farm work is not pressing.

Plowing Under Manure

It is usually best to apply manure as a surface dressing and mix it with the soil by discing. If, however, it is desired to mellow and deepen the soil, it is better to bury the manure deeply. Light, sandy soils derive the greatest benefit from manure when spread on the surface and covered with a shallow furrow.

Coarse, trashy manure should be covered deeply, because it will decay better, by reason of the greater quantity of moisture.

The purpose of green manure (green vegetation) is to deepen the soil and supply humus, so it should be well covered, especially when the growth is heavy.

There is danger in plowing under a green crop. If the weather is unduly wet, it is liable to decay too rapidly, making the soil sour by developing acid. On the other hand, if there are insufficient rains after plowing, the furrow-slice is apt to remain loose and dry out, there being no well-established connection with the subsoil.

Therefore, when a green crop or a heavy coat of manure is to be turned under, it is preferable to plow early so the organic matter will have ample time to decay and the soil to become settled before seeding time.

The Seed Bed

In order to secure the ideal condition for seed germination and plant growth, a seed-bed for planting should not be too deep and mellow. The soil should be mellow and well pulverized only about as deep as the seed is to be planted. Below this the soil should be firm and well settled, making a good connection with the subsoil, so that the water stored therein may be drawn up into the surface soil. The firm soil below the seed supplies the needed moisture, while the mellow soil above it allows sufficient circulation of air to supply oxygen and favors the warming of the soil by gathering the heat of sunshine during the day and acting as a blanket to conserve the soil heat during the night.

The mellow soil above the seed also conserves the soil moisture by keeping the water from reaching the surface, where it would be rapidly lost by evaporation.

This same condition favors the upward growth of the young shoots into the air and sunshine.

The too mellow, deep seed-bed is almost wholly dependent upon rains for sufficient moisture to germinate the seed and start the young plants.

If the crop starts, it is apt to be injured by short periods of dry weather, because the loose surface soil dries out rapidly. In such a seed-bed the crop is also more apt to freeze out in winter than a crop grown on the ideal seed-bed described above.

Careful, judicious plowing is the most important operation in the preparation of an ideal seed-bed, and, if poorly done, no amount of subsequent surface tillage will correct the mistake.

To plow intelligently is one secret of success in farming.

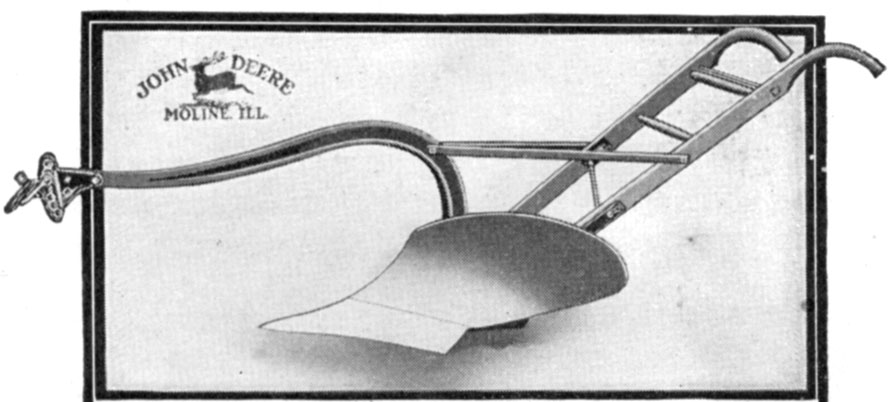

John Deere Plow Bottoms

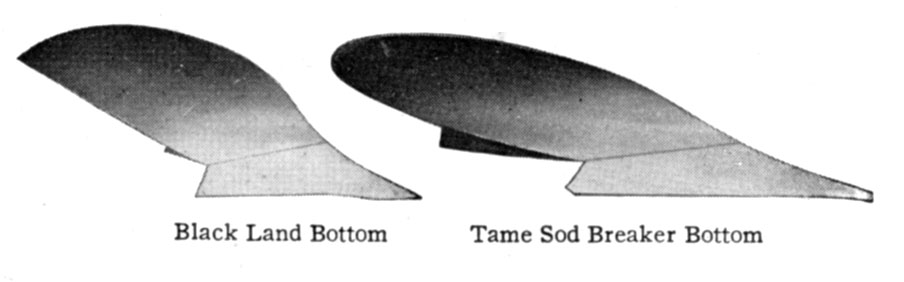

As a general proposition, moldboard plows are of two types — breakers and stirring plows, that is, plows for sod or for old ground.

We make both types in a great variety of styles.

Our breakers have long, sloping moldboards, which invert the furrow-slice without breaking the sod.

They are made in styles suitable for either deep or shallow breaking, for tame sod or tough, prairie sod. Rod breakers are made in both heavy and light weights.

John Deere stirring bottoms, of which the stubble plow is typical, have an abrupt turn to the moldboard.

Besides inverting the furrow-slice, they thoroughly pulverize the soil, making it mellow and of fine texture.

Intermediate in form between these two extremes, there are special and general-purpose John Deere bottoms to meet all soil conditions.

The moldboards and shares of the larger sized plows—12 inches and over—are double shinned. That is, they have an extra layer of hard steel welded on at that point where wear is greatest. This more than doubles the life of such plows.

With few exceptions, the wearing parts of John Deere bottoms — moldboards and shares — are made of the best soft-center steel, which is very hard, fine-grained, and takes a high polish.

The soft, tough center layer gives the necessary strength, while the hard, outer layers give the great scouring and wearing qualities.

For some soils that scour easily, we make the bottoms of solid steel, which has a high natural temper.

The scouring qualities of John Deere bottoms are also due to their shape—the result of 70 years of successful plow building.

They cut and turn the furrow-slice with the least amount of friction, but secure the best results.

Remember, John Deere bottoms have keen cutting qualities. They enter the ground like a thin wedge enters and splits a log.

New Steel Frame Construction

We have now grouped several of our styles of plows, and built them so that parts are interchangeable on all the members of each group.

For example, our "N" series, which includes both stubble and general-purpose plows, all take the same share and landside, having exactly the same style of frog.

When purchasing an extra share, the owner of one of these plows does not have to remember its exact brand. He merely needs to call for the correct size. This is a big convenience.

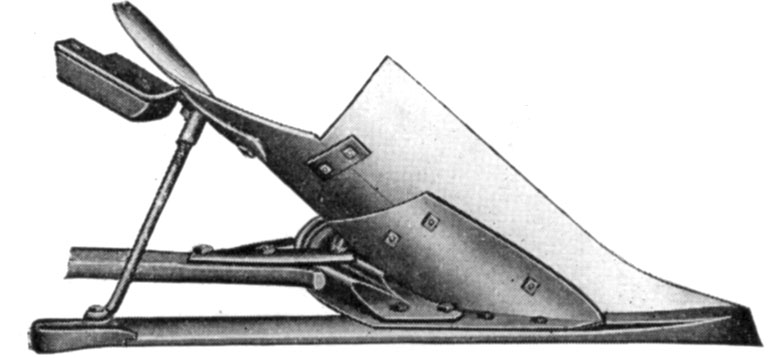

Operating Walking Plows

A walking plow is very sensitive to soil conditions, depth of plowing, the hitch, the set of the rolling coulter and the share.

Many farmers have experienced a change in the running of their plows from one day to the next without knowing why.

It probably rained during the night, softening the soil so the suction of the share caused it to wing slightly or run over on one side. Depth of plowing is often changed with the same result.

Two different farmers often use the same plow under the same soil conditions with different results — the one is satisfied and the other is not. In all probability the latter used an evener that was either too long or too short, or the pull of this team was not properly distributed.

Set of the Shares

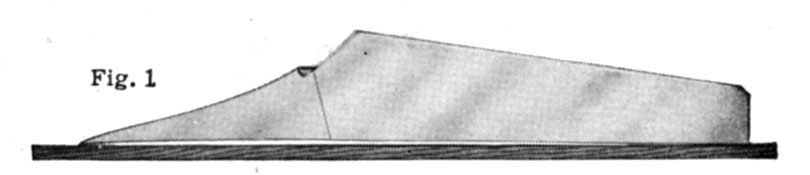

As a general rule, a walking plow should be balanced about the point and run level.

By referring to the accompanying illustrations, it is easy to see why a plow wings, runs on its nose, or tries to run out of the ground.

Fig. 1 shows the set of the share point to secure penetration under all ordinary conditions. Note clearance or space under the center of the landside piece of share. This is the "suction" and should be about one-eighth of an inch. Slightly more suction is given for very hard plowing.

Fig. 2 shows the point improperly set. Such a point will tend to lift the plow out of the ground. Shares worn round on the bottom produce the same result.

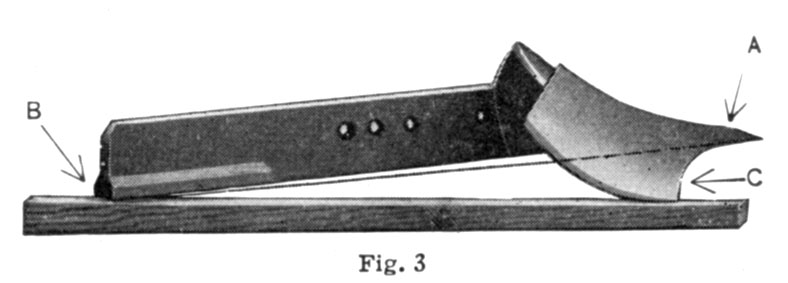

In Figs. 3 and 4, note the straight edge extending from the heel of the landside across the heel of the share.

At point C, Fig. 3, the edge of the share has quite a wide bearing on the straight edge. This should be about 1 inch for 12-inch plows, 1 ¼ inches for 14-inch plows, and 1 ½ inches for 16- inch plows.

For very hard plowing the edge of the share is turned down, as shown at C, Fig. 4.

When John Deere plows leave the factory they are adjusted for average soil conditions and depths, considering, of course, the kind of work for which each plow is intended.

If, for any reason, the plow wings over on the landside, the edge of the share should be turned down slightly. If it wings over the other way, the share has too much penetration and the edge should be turned up.

Any farmer can do this work if he uses a little care. Turn the plow bottom side up, hold a heavy sledge or iron bar on one side and hammer the other side carefully with a light hammer or monkey-wrench. Turn only about four inches of the edge extending from the heel toward the point. Do not turn the edge too much—about one-sixteenth of an inch is usually enough.

Everything else being right, this simple operation will insure level running of the plow under all conditions. But be sure all other conditions are right before touching the share.

Setting Rolling Coulters

It is important to know how to set a rolling coulter if one is used.

Ordinarily, its center should be directly over the share point.

When the ground is covered with wet corn stalks, it is desirable to set the coulter high, and somewhat back of the point. In this position it gets on top of the stalks, and tends to shear them between the blade and the shin of the plow.

Sometimes, in very trashy ground, it is an advantage to set the rolling coulter well forward.

For very hard ground do not set the coulter ahead of the point, because it will then have a tendency to lift the plow out of the ground.

For stubble ground, the rolling coulter should be set five-eights of an inch outside of the landside, and run one-third to one-half the depth of the furrow. For sod it is usually set somewhat closer to the landside, and should run the entire depth of the furrow.

If the rolling coulter does not caster, be sure that it is set just right. If set at an angle to the cut it will lead the plow toward or from the land, disturbing the proper width of cut.

Finally, see that the hitch is right, that the rolling coulter is working properly, and that the share has the proper penetration.

Use Right Hitch

Do not use wagon doubletrees for plowing. Unless doubletrees are the right length they will not give best results.

A good rule is to make the doubletree three times as long as the furrow is wide. For a 12- inch plow it should be 36 inches long, 42 inches for a 14-inch plow, and 48 inches for a 16-inch plow. This rule applies principally when two horses are used. There is usually less difficulty experienced with the three-horse hitch.

On hillsides it is a good plan to use a swivel hitch, because the extra upward swing of one end of a rigid doubletree will wing the plow. A chain link or ring between the clevises will correct this.

John Deere Stubble Plows

These plows are built for farmers who grow cultivated or small-grain crops principally, and who want to pulverize, thoroughly, the soil when plowing.

They are used extensively in localities where wheat, corn, etc., are grown year after year on the same ground.

The moldboards for this series are short, high, and have an abrupt turn. They scour perfectly under ordinary conditions, leaving the soil in a mellow, friable condition.

The double beaded steel beam has a high curve, giving plenty of clearance for trash.

Moldboards and shares are made of best quality hardened, soft-center steel, and are double shinned. This means maximum serviceability.

Remember Deere & Company use the best quality of soft-center steel, which consists of three layers of steel – a soft, tough layer between two very hard ones – fused solidly together. The layers are uniform in thickness, so there is no wearing through in spots.

For ashy, sticky, gumbo, or other difficult scouring soils, we made special stubble plows, which handle them most satisfactorily.

John Deere General Purpose Plows

Especially adapted for farmers who rotate their crops, or practice diversified farming and have tame sod as well as stubble or old ground to plow.

The moldboards have a somewhat longer, slower turn than those of the stubble series. They have excellent pulverizing qualities, but do not break up the furrow-slice when used in sod.

In the latter, they lap the furrows sufficiently to bury the green vegetation in loose soil, which prevents further growth and hastens decay. This also favors cultivation with the disc harrow, or other tillage implements.

These plows have best steel construction, pull easy, and will wear a long time.

Both shares and moldboards are made of the best soft-center steel and double shinned. That is, an extra layer of hard steel is welded on at the point where wear is greatest. The double shin rightly placed more than doubles the life of a plow – a very important consideration.

John Deere general-purpose plows are made in styles to meet all conditions, no matter what they are.

John Deere Eastern General Purpose Plows

These plows are used for all-round work in Michigan, Indiana, the eastern states, and other localities where the soil is of a sandy nature.

This means that they will work equally well in stubble, old ground, or tame sod.

The principal special features of this series are a low, wide throat and a wide, easy turn of the moldboard.

The former produces a clean furrow to walk in while the latter gives lightness of draft. Regularly furnished with hardened, soft-center steel moldboards and shares, also hardened steel landside with cast slip heel.

Handles are straight and interchangeable on plows of same size and pattern.

For gravelly or stony soils they can be equipped with chilled, cast-iron shares and landslides, the latter having a cast-iron slip heel which is easily replaced.

This style of plow has the scouring qualities of a full steel plow, is moderate in price and suitable for work in new ground.

With the various equipments mentioned, the owner of one of these plows has a combination outfit which is very convenient and serviceable, especially if his fields vary in soil composition.

John Deere Mixed Land Plows

A light loam or mixture of sand and clay requires a plow of the general-purpose pattern, but the steel does not have to be of such a high temper to scour perfectly.

John Deere mixed-land plows are adapted for either stubble or tame sod plowing in mixed soils, and are preferable to chilled plows, because they handle easier.

The bottoms of John Deere mixed-land plows are much lighter than ordinary chilled bottoms. This is one reason why they pull easier and handle easier than chilled plows. Besides this, they have the nice running qualities found only in John Deere plows – they save both team and operator.

Regularly equipped with solid steel moldboards, solid steel landsides and cast steel shares. Also straight handles, like other John Deere plows. Landsides have cast slip heel.

Note that soft-center steel is not used. For soils of this kind it is of no special advantage, because they scour easily. It would add to the cost.

For wearing, scouring and covering qualities, these plows are unequaled for the character of work they are intended to do.

Extensively used.C

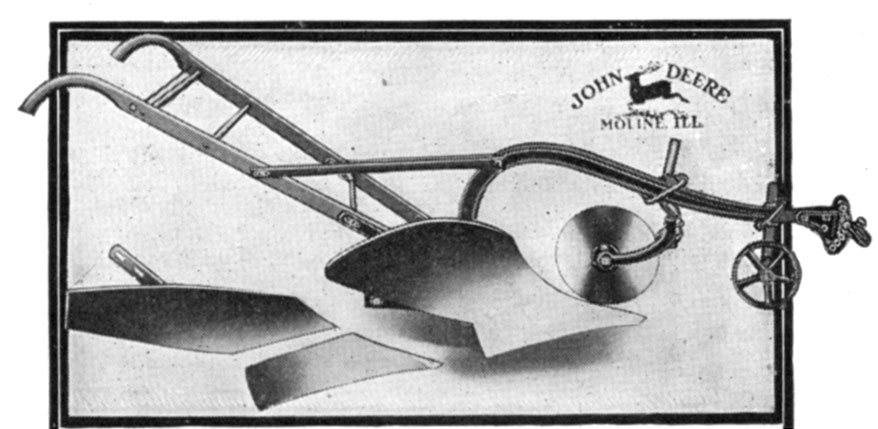

John Deere Combination Old Ground and Breaking Plow

In a newly-opened prairie country it is often necessary for the farmer to have both old-ground and prairie breakers.

For such conditions our combination plow is a very handy, economical and serviceable implement.

With the exception of the landside, which is low, this plow is like our regular general-purpose plows.

It is easily converted into a prairie breaker by substituting a moldboard and share of the breaker type. These parts fit perfectly.

The old-ground bottom is made of hardened softcenter steel, while the breaker bottom has a cast steel share and a solid steel moldboard.

The breaker moldboard is of the Deere Prairie pattern.

Caster rolling coulter and gauge wheel goes with each combination plow.

A fin cutter or a Quincy cutter furnished as extras when specially ordered.

Investigate this plow if you are developing a prairie farm.

How Often Plow Garden With A Tractor

Source: https://smallfarmersjournal.com/the-science-and-art-of-plowing/

Posted by: browntheird.blogspot.com

0 Response to "How Often Plow Garden With A Tractor"

Post a Comment